Copyright © 2016 Hemadri Cements

All rights reserved.

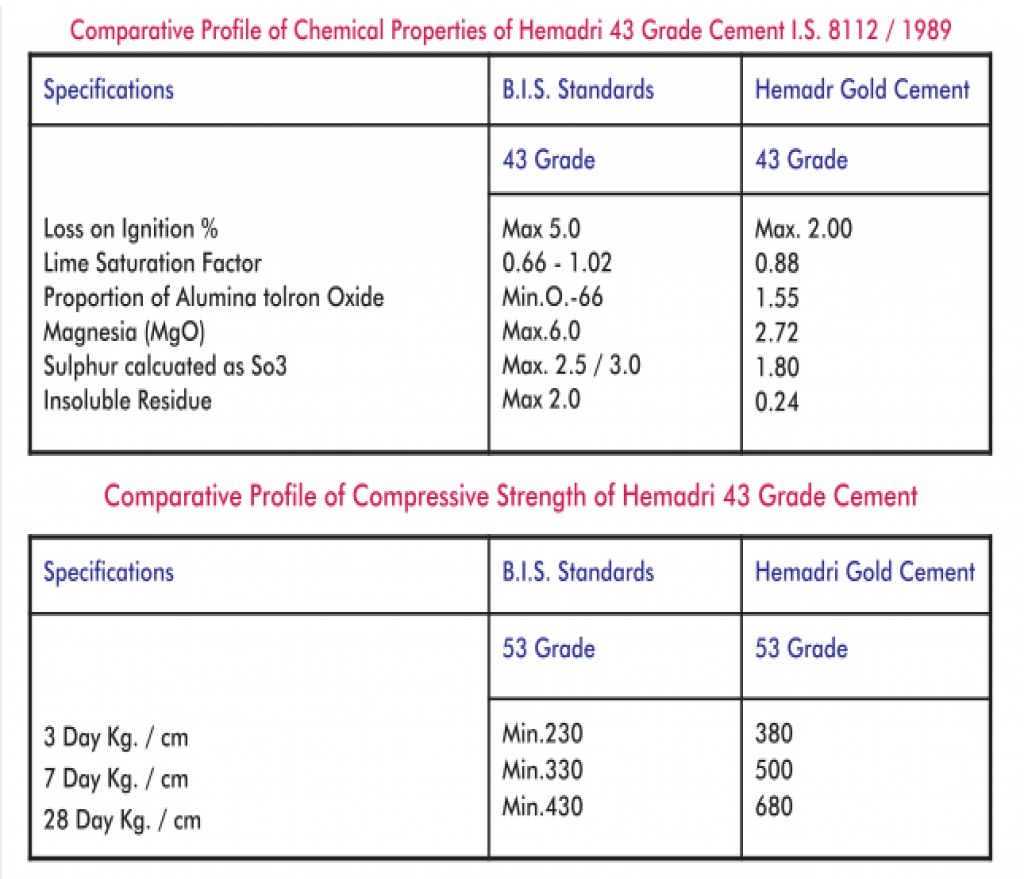

PHYSICAL PROPERTIES OF HEMADRI 43 GRADE CEMENT

PHYSICAL PROPERTIES OF HEMADRI 43 GRADE CEMENT

The values reflect an average sample of Hemadri 43 Grade Cement Hemadri Gold 53 Grade stands unmatched in terms of initial strength leading to early completion of construction thus reducing costs. Being nearly 40% finer than B.I.S Specifications for cement in this category, It enhances the smoothness, density and durability of the structures. It has the lowest alkali component thus ensuring high strength concrete with a tower cement consumption.

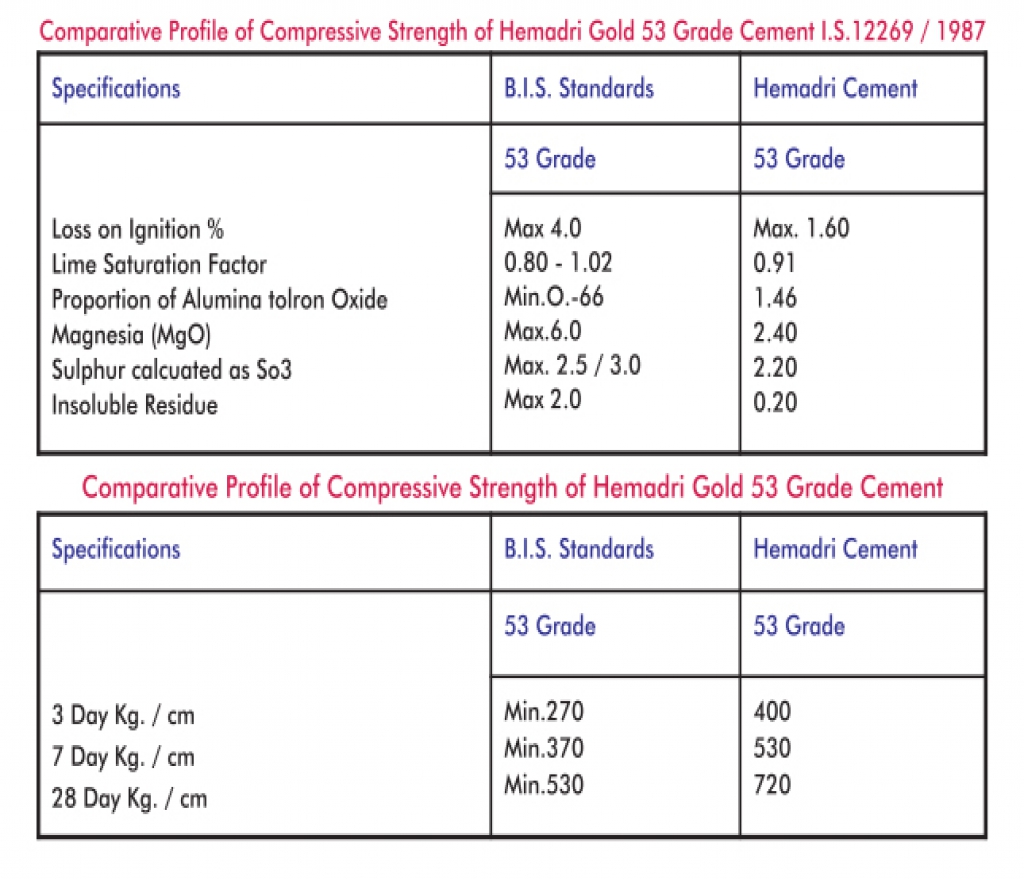

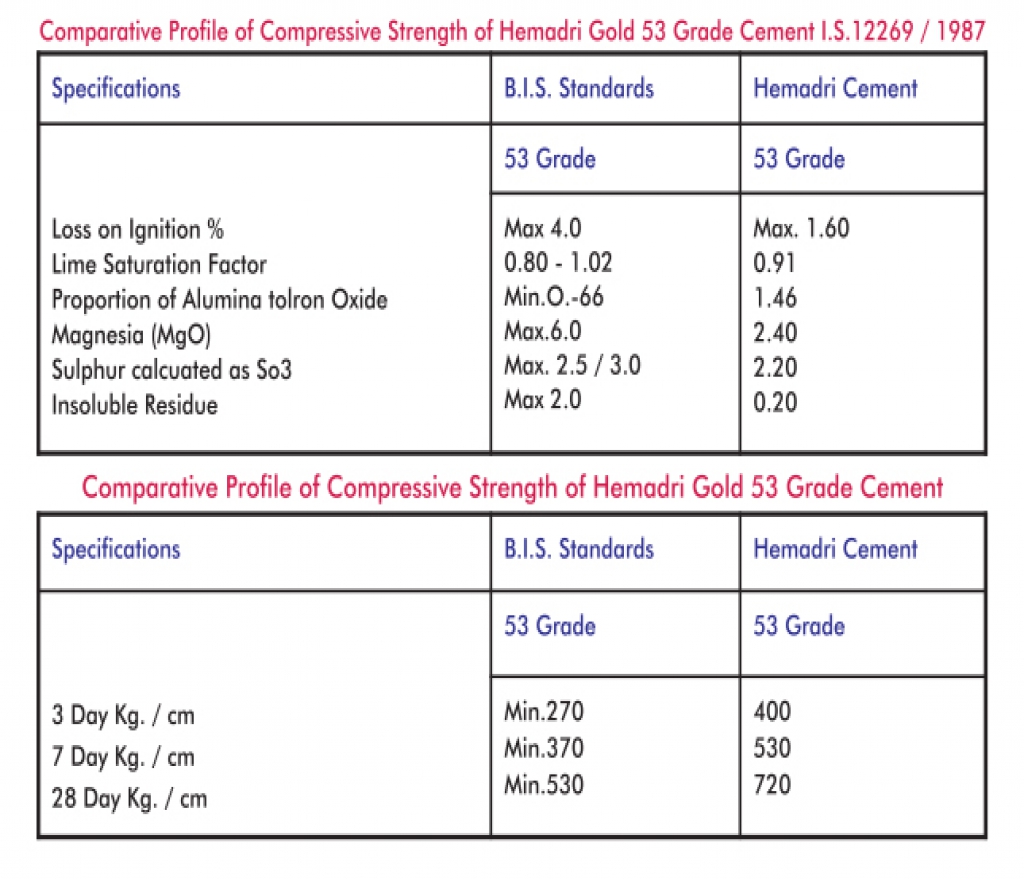

COMPRESSIVE STRENGTH OF HEMADRI GOLD 53 GRADE CEMENT

COMPRESSIVE STRENGTH OF HEMADRI GOLD 53 GRADE CEMENT

Hemadri Gold 53 Grade assures long life concrete with maximum saving because of 36% higher final compressive strength. It finds its best use in construction of Commercial and industrial Complexes, Multi – storey Buildings Road and Runways Bridges, Flyovers and culverts & Water Tanks, Concrete Bunds and Aqua ducts Plastering and Finishing Pre-stressed Concrete Constructions etc.

COMPRESSIVE STRENGTH OF HEMADRI 43 GRADE CEMENT

COMPRESSIVE STRENGTH OF HEMADRI 43 GRADE CEMENT

Hemadri 43 Grade and Hemadri Gold 53 Grade cements not just adhere to but even exceed the standards laid down by BIS. A comparative profile would highlight the fact. The value of Hemadri 43 Cement even supersede the requirement of 53 Grade O.P.C as per B.I.SHemadri 43 Grade Surpasses the stringent quality standards set by B.I.S on compressive strength, ultra fineness and setting time. In fact its 28th day compressive strength is a phenomenal 58% higher when compared to B.I.S specifications. Ultra- fine Hemadri 43 provides a lower water- cement ratio, construction costs and affords a better finish. The final setting time of Hemadri 43 Grade is one of the lowest by industry standards, which speeds up construction, chemical aggregate reactions are minimized because Hemadri 43 Grade is of the lowest alkali composition thus making it the most durable concrete in this category.With these attributes, Hemadri 43 Grade is the ideal cement for construction activities such as Residential and commercial Complexes Compound walls, Grills, Door Frames Spun Pipes and Poles manufacturing PCC solid and Hollow Concrete Bricks etc.

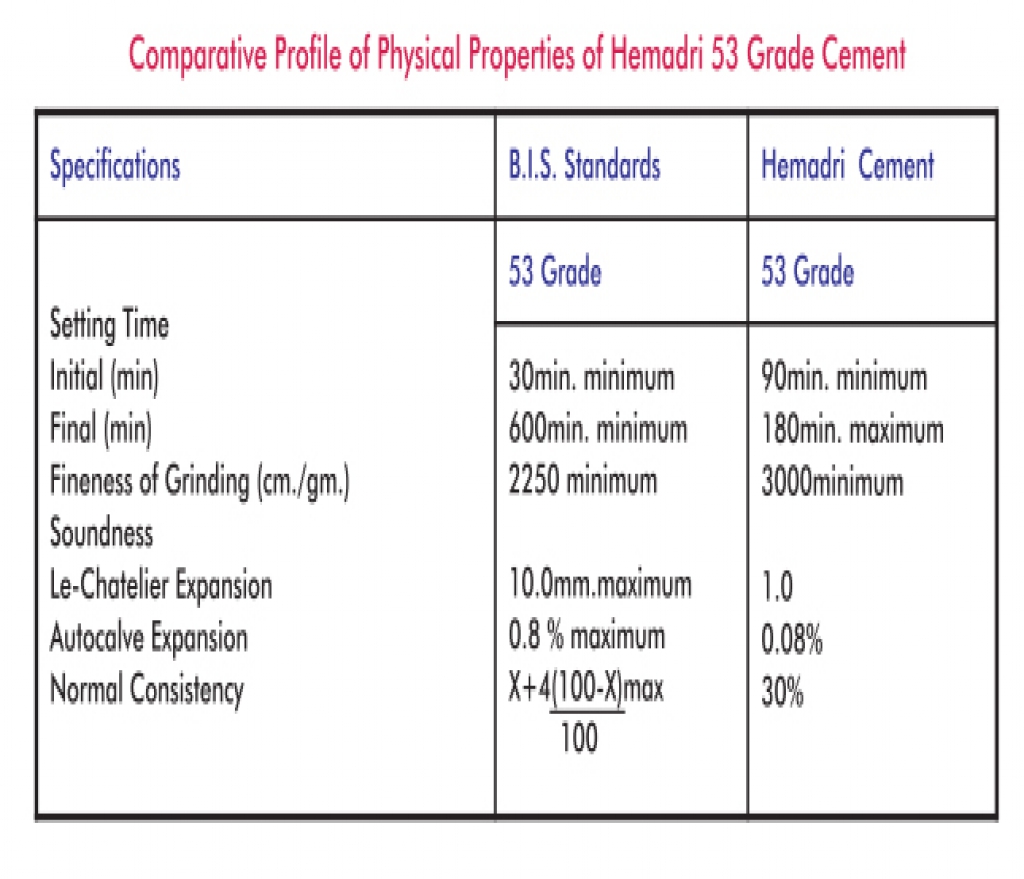

PHYSICAL PROPERTIES OF HEMADRI GOLD 53 GRADE CEMENT

PHYSICAL PROPERTIES OF HEMADRI GOLD 53 GRADE CEMENT

The factory of Hemadri Cement Ltd. (vedadri) incorporates the latest technology for manufacturing cement on par with the current world standards. The factory is spread over 150 acres of land along with a fully developed staff colony. The core machinery of this modern day dry process plant has been supplied by Walchandnagar (India) Ltd. Which has a technical collaboration with Polyusius of Germany. The functioning of the entire factory can be controlled locally as well as remotely through a centralized computer network incorporating the latest software package which monitors the production of cement on a continuous basis. This ensures efficiency in operation and helps to maintain effective quality and cost control on the production of cement at every stage of its manufacture

wwe